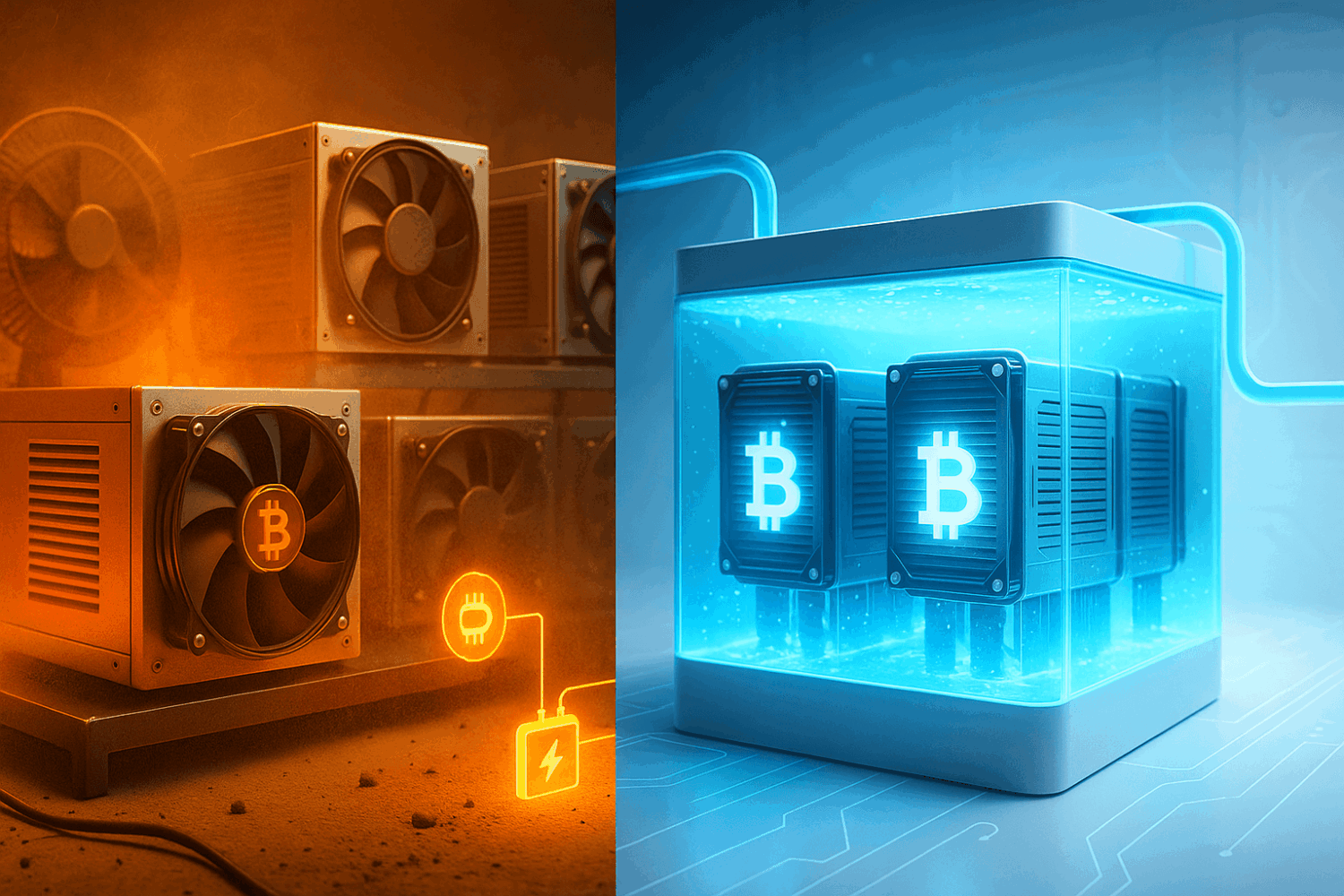

Heat kills profits. Every degree above optimal operating temperature costs you money. While amateur miners struggle with scorching hot ASIC miners and skyrocketing electricity bills, professionals are quietly revolutionizing the industry with liquid cooling technology that most people have never heard of.

Immersion cooling isn’t just the future of crypto mining—it’s happening right now. Major mining operations are achieving 30-50% better performance while slashing energy costs and extending hardware lifespan by years. The gap between air-cooled operations and immersion cooling systems is widening every month.

This isn’t theoretical tech talk. This is about survival in an industry where thermal management separates winners from losers. Because when your competition is running cooler, faster, and more efficiently, you’re not just losing money—you’re getting left behind permanently.

Warning: What you’re about to learn will make you question every cooling decision you’ve ever made.

The Heat Crisis: Why Cooling for Mining Determines Who Survives

The brutal reality: Heat is the silent killer of mining operations.

Standard ASIC miners generate enough heat to literally cook food. A single Antminer S19 Pro produces approximately 10,500 BTU/hour—equivalent to a large space heater running continuously. Multiply that by dozens or hundreds of miners, and you’re operating a furnace, not a mining farm.

Performance degradation starts immediately when temperatures climb:

- 75°C: 10% hash rate reduction

- 85°C: 25% performance loss

- 95°C: Automatic shutdown protection kicks in

Most miners have no idea their equipment is throttling performance due to heat. They blame network difficulty or hardware issues while their rigs literally slow down to prevent thermal damage.

The energy consumption nightmare: Overheated mining equipment consumes 15-30% more electricity while producing less hash. You’re paying more for worse performance. It’s the worst possible combination.

Hardware lifespan destruction: Excessive heat reduces ASIC miner lifespan from 3-5 years to 18-24 months. The main causes of electronic equipment failures stem directly from thermal stress. Heat doesn’t just hurt profits—it destroys assets.

Traditional air cooling simply cannot handle the thermal demands of modern mining operations. The physics don’t work when you’re packing kilowatts of heat generation into confined spaces.

Air Cooling: The Outdated Standard That’s Holding Everyone Back

Air cooling is dying a slow, expensive death.

Traditional cooling methods made sense when mining was simpler and ASIC miners generated less heat. Those days are over. Modern mining hardware produces 3-4 times more heat per unit than equipment from just five years ago.

The fundamental problem: Air can only absorb and move so much heat. Physics limits air cooling effectiveness regardless of how many fans you install or how fast they spin.

Noise pollution destroys neighborhoods—and relationships. A typical air-cooled mining farm generates 75-85 decibels continuously. That’s equivalent to city traffic or a garbage disposal running 24/7. Home mining becomes impossible when neighbors start complaining.

Energy waste compounds problems: Fans and ventilation systems consume 10-15% of total facility power. You’re literally paying to move hot air around instead of generating revenue.

Seasonal performance variations make planning impossible. Summer heat waves can reduce mining capacity by 30-40% when ambient temperatures soar. Your most profitable months become your worst performing months.

The mining industry has outgrown air cooling capabilities. Smart operators recognized this years ago and started transitioning to liquid cooling solutions.

Immersion Cooling Revolution: How Liquid Technology Changes Everything

Immersion cooling for crypto mining represents the most significant thermal management breakthrough in the industry’s history.

The concept sounds radical but works brilliantly: Submerge your entire ASIC miner in specially designed dielectric liquid. The coolant absorbs heat directly from components while maintaining perfect electrical isolation.

The physics advantage is overwhelming: Liquid coolant has 1,000 times better thermal conductivity than air. Heat transfer efficiency improves by orders of magnitude.

Dielectric fluids eliminate electrical conductivity concerns while providing superior cooling performance. These engineered liquids cost more than water but protect electronic equipment from moisture damage while delivering exceptional heat removal.

Noise reduction becomes dramatic: Immersion cooling eliminates the need for chassis fans entirely. Sound levels drop from 75+ decibels to under 40 decibels. You can actually have a conversation next to an immersion mining system.

Performance gains are immediate and measurable:

- 15-25% hash rate improvement due to optimal operating temperatures

- 20-30% reduction in power consumption per hash generated

- 300-500% increase in hardware lifespan

Professional mining operations treat immersion cooling as essential infrastructure, not optional equipment.

Immersion Cooling Methods: Single-Phase vs. Two-Phase Systems Explained

Not all immersion cooling systems are created equal. Understanding the differences could save you thousands in mistakes.

Single-Phase Immersion Cooling: The Workhorse

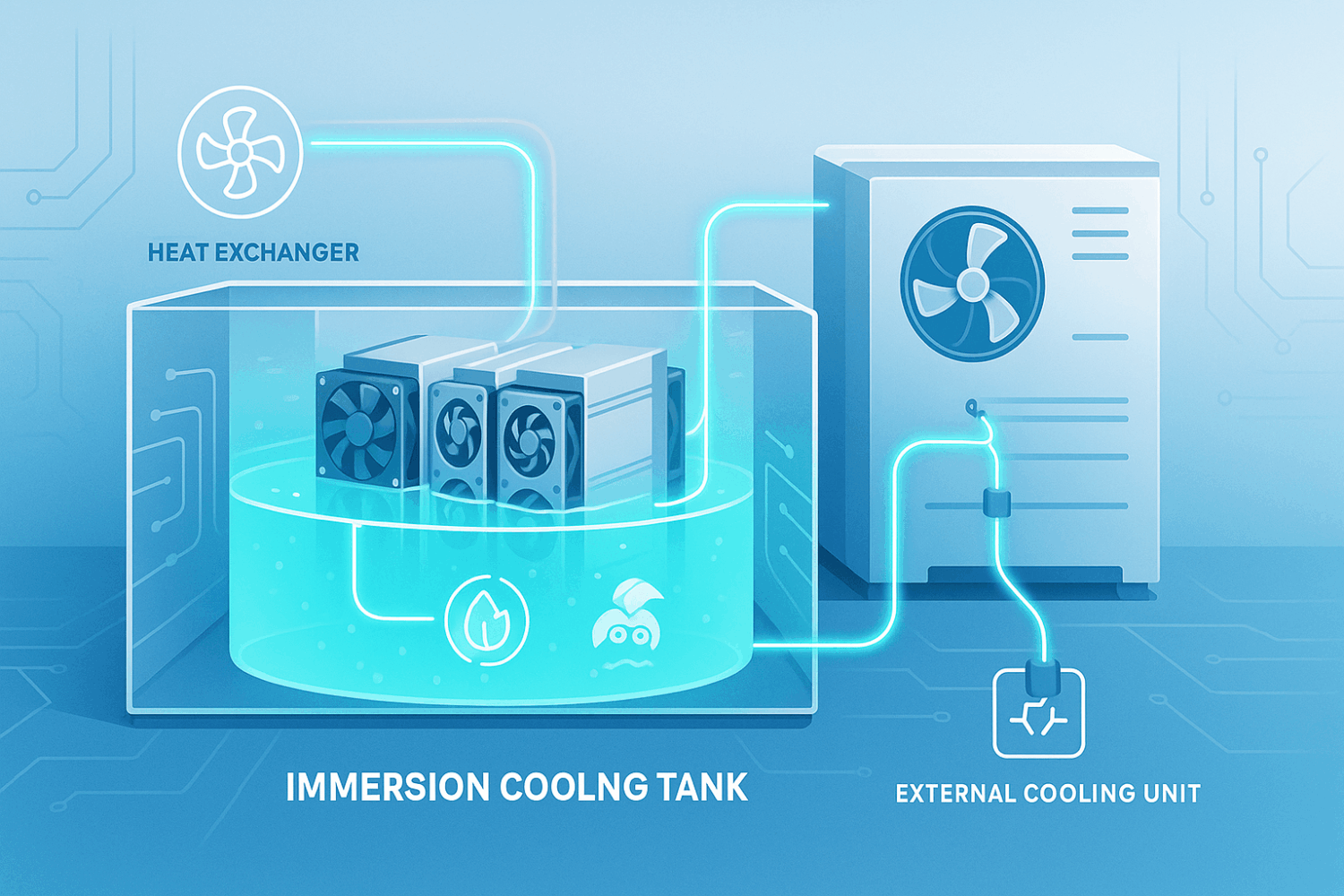

Single-phase immersion keeps coolant in liquid form throughout the entire cooling cycle. The liquid circulates through heat exchangers where external cooling removes accumulated heat.

Advantages of single-phase systems:

- Lower initial investment costs

- Simpler maintenance requirements

- Proven reliability in data center applications

The single-phase process: Hot coolant rises naturally (convection) or gets pumped to heat exchangers. External cooling (air or water) removes heat before returning cooled liquid to the immersion tank.

Two-Phase Immersion Cooling: The Performance King

Two-phase immersion cooling allows coolant to boil and condense in a closed-loop system. The phase change process provides exceptional heat transfer efficiency.

The two-phase advantage: Boiling liquid absorbs massive amounts of heat during phase change. Vapor condenses on cooling surfaces and returns to liquid state. This process handles much higher heat densities.

Performance benefits:

- 40-60% better heat removal compared to single-phase

- Handles extreme overclocking scenarios safely

- More compact system design possible

The trade-off: Higher complexity and cost. Two-phase systems require more sophisticated monitoring and control systems.

Large-scale mining operations increasingly choose two-phase systems despite higher costs because performance gains justify the investment.

Game-Changing Benefits: Why Immersion Mining Dominates Every Metric

The performance advantages compound rapidly once you implement immersion cooling properly.

Thermal Performance That Defies Physics

ASIC miners maintain optimal temperatures regardless of ambient conditions. External heat waves don’t impact internal operations. Your mining capacity stays constant year-round.

Overclocking becomes safely practical: Liquid cooling handles 25-40% power increases without thermal stress. Higher hash rates generate more revenue from the same hardware investment.

Energy Efficiency That Transforms Economics

Power consumption drops 20-30% for the same hash output. The efficiency improvement pays for cooling system costs within 12-18 months in most scenarios.

Cooling equipment energy requirements drop dramatically. No chassis fans, fewer facility fans, and more efficient heat rejection. Total facility power consumption can decrease despite higher mining performance.

Hardware Longevity That Protects Investments

ASIC miner lifespan extends 3-5 times normal expectations when properly cooled. Instead of replacing miners every 2 years, quality hardware lasts 5-7 years.

Maintenance intervals increase: Cooler operation reduces component stress. Fewer failures mean lower maintenance costs and higher uptime percentages.

Operational Advantages That Enable Scaling

Density improvements allow more miners per square foot. Immersion cooling systems typically achieve 2-3 times higher power density than air-cooled installations.

Location flexibility increases: Quiet operation enables mining in residential and commercial areas where noise restrictions previously prevented operations.

The cumulative effect of these benefits creates sustainable competitive advantages that compound over time.

The Reality Check: Immersion Cooling Challenges That Destroy Unprepared Operations

Immersion cooling isn’t magic. Implementation challenges kill more projects than technical limitations.

Capital Investment Shock

Initial costs are substantial: A professional immersion tank for 20-30 ASIC miners costs $15,000-25,000 before coolant. High-quality dielectric fluid adds $3,000-5,000 per tank.

Infrastructure requirements often get underestimated. Heat exchangers, pumps, monitoring systems, and facility modifications add 30-50% to base equipment costs.

Financing challenges: Traditional equipment financing doesn’t always cover immersion cooling infrastructure. Plan for higher upfront capital requirements.

Technical Complexity That Overwhelms Amateurs

Coolant management requires constant monitoring. Fluid levels, temperature gradients, and contamination prevention demand professional attention.

Maintenance procedures differ dramatically from air cooling. Removing miners for service requires careful coolant handling and contamination prevention.

Training requirements: Staff must understand liquid cooling principles, safety procedures, and emergency protocols. Mistakes can destroy expensive equipment instantly.

Supply Chain Dependencies

Specialized coolant isn’t available at local hardware stores. Supply disruptions can shut down operations if backup fluid isn’t maintained.

Component replacement often requires specialized parts with longer lead times than standard air cooling equipment.

Professional mining operations budget 6-12 months for complete immersion cooling transitions including staff training and system optimization.

Air vs. Immersion: The Performance Gap That Determines Winners

The comparison isn’t even close when you analyze real-world performance data.

Thermal Management Effectiveness

| Metric | Air Cooling | Immersion Cooling |

| Max sustainable temp | 75-85°C | 45-65°C |

| Ambient temp impact | High | Minimal |

| Hot spot elimination | Poor | Excellent |

Air cooling struggles with hot spots and uneven temperature distribution. Immersion cooling provides uniform thermal management across all components.

Performance and Efficiency

Hash rate stability: Air-cooled systems experience 15-30% performance variations. Immersion systems maintain consistent output regardless of external conditions.

Energy efficiency: Immersion cooling typically achieves 20-30% better power efficiency (W/TH) compared to air cooling under identical conditions.

Overclocking capability: Air cooling limits overclocking to 5-10% above stock settings. Immersion cooling safely handles 25-40% power increases.

Operational Economics

Maintenance costs: Air cooling requires frequent fan replacements and filter changes. Immersion systems need minimal maintenance once properly configured.

Hardware replacement cycles: Air-cooled miners typically last 18-24 months in demanding environments. Properly cooled immersion miners often exceed 5-year lifespans.

The total cost of ownership analysis consistently favors immersion cooling for serious mining operations.

Cutting-Edge Innovations: How Technology Leaders Are Reshaping Cooling

Innovation in cooling technology is accelerating rapidly as mining demands increase.

Marathon Digital’s MARA 2PIC700 Revolution

Marathon Digital Holdings pioneered commercial-scale two-phase immersion cooling with their MARA 2PIC700 system. This system handles 700kW of mining equipment in a single immersion cooling suite.

Performance achievements:

- 35% improvement in power efficiency

- 50% reduction in facility cooling requirements

- 90% noise reduction compared to air-cooled facilities

The game-changing insight: Large-scale implementation proves immersion cooling economics work at industrial scale.

Modular Immersion Systems

Pro9 immersion mining enclosure and similar products make immersion cooling accessible for smaller operations. These systems are ideally sized for home mining operations.

Key innovations:

- Plug-and-play installation reduces technical barriers

- Standardized coolant volumes simplify maintenance

- Integrated monitoring provides professional-grade controls

Hybrid Cooling Approaches

Direct liquid cooling and immersion cooling combinations optimize different system components. Primary cooling methods can be customized based on specific hardware requirements.

Advanced heat recovery: Professional installations capture waste heat for secondary applications, improving overall energy efficiency and creating additional revenue streams.

The technology evolution continues accelerating as mining operations demand better performance and efficiency.

Economic Reality: How Cooling Choices Determine Mining Profitability

Your cooling decision impacts every aspect of mining economics.

Operational Cost Analysis

Energy consumption differences compound rapidly:

- Air cooling: $0.08-0.12 per kWh effective cost (including cooling overhead)

- Immersion cooling: $0.06-0.08 per kWh effective cost (higher efficiency)

For a 100kW mining operation: Immersion cooling saves $1,500-3,000 monthly in electricity costs alone.

Hardware Investment Protection

Depreciation rates vary dramatically:

- Air-cooled miners: 50-60% annual depreciation due to heat damage

- Immersion-cooled miners: 20-30% annual depreciation with proper thermal management

Resale value retention: Well-maintained immersion-cooled equipment commands premium prices in secondary markets.

Scalability Economics

Facility efficiency improves with immersion cooling:

- 2-3x higher power density reduces real estate costs per hash

- Lower HVAC requirements reduce facility infrastructure investments

- Reduced maintenance staffing needs due to higher reliability

Return on investment: Most professional immersion cooling installations achieve positive ROI within 18-24 months through combined efficiency gains and hardware longevity improvements.

The economic advantages become more pronounced as operations scale and energy costs increase.

Environmental Impact: How Cooling Technology Shapes Mining’s Future

Environmental considerations increasingly influence operational decisions as regulatory pressure intensifies.

Energy Consumption Reduction

Immersion cooling typically reduces total facility energy consumption by 15-25% compared to air cooling systems. Lower energy usage directly reduces carbon footprint and environmental impact.

Heat recovery opportunities: Captured waste heat can provide space heating, hot water, or industrial process heat. Some operations achieve 40-50% total energy efficiency when waste heat gets utilized effectively.

Noise Pollution Elimination

Traditional air cooling generates significant noise pollution that limits mining location options and creates community conflicts.

Immersion cooling eliminates noise issues entirely, enabling mining operations in residential and commercial areas previously unsuitable for crypto mining.

Resource Utilization Efficiency

Hardware longevity improvements reduce electronic waste generation. Extending ASIC miner lifespans from 2 years to 5+ years dramatically reduces manufacturing demand and associated environmental impact.

Coolant recycling: Modern dielectric fluids can be filtered and reused multiple times, minimizing waste generation from cooling operations.

Environmental compliance advantages position immersion-cooled operations favorably for future regulatory requirements.

Implementation Blueprint: Your Roadmap to Immersion Cooling Success

√ Assess Current Operations

- Calculate total heat generation from existing mining equipment

- Evaluate facility infrastructure capacity for liquid cooling systems

- Document current cooling costs including energy and maintenance

√ Design System Architecture

- Choose single-phase or two-phase based on performance requirements and budget

- Size immersion tanks for current miners plus 25-50% expansion capacity

- Plan heat rejection systems (dry coolers, cooling towers, or building integration)

√ Select Professional Partners

- Research liquid cooling experts with mining experience specifically

- Verify installation capabilities and post-installation support

- Demand references from similar mining operations

√ Prepare Infrastructure

- Upgrade electrical systems to handle higher power densities safely

- Install proper drainage and spill containment systems

- Implement fire suppression suitable for dielectric fluids

√ Plan Migration Strategy

- Phase implementation to maintain mining operations during transition

- Train technical staff on immersion cooling procedures and safety

- Establish coolant supply chains and emergency procedures

√ Optimize Performance

- Monitor thermal performance continuously during initial operation

- Fine-tune coolant flow rates and heat exchanger operation

- Document performance improvements to justify additional investments

√ Scale Operations

- Expand immersion capacity based on proven ROI and performance

- Integrate waste heat recovery for additional efficiency gains

- Consider advanced monitoring and automation systems for large installations

The bottom line: Immersion cooling isn’t optional for serious mining operations anymore. It’s the difference between surviving and thriving in an increasingly competitive industry.

Early adopters are already seeing the benefits: Lower costs, higher performance, longer equipment life, and operational flexibility that air cooling simply cannot match.

The transition is happening now. Every day you delay switching to immersion cooling is another day your competition gains ground you’ll never recover.

Choose wisely. Choose liquid. Choose to dominate.